Degrees & Programs at CEM

The College of Engineering and Mines offers 9 undergraduate degrees,

Eight of our undergraduate programs are accredited by ABET.

We also offer Master's degrees in 7 different majors as well as a Ph.D. in Engineering.

March 20, 2024

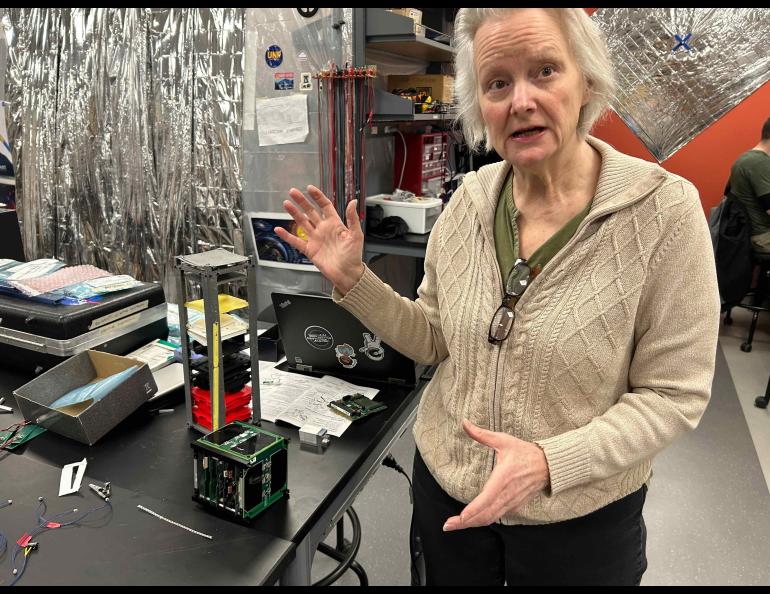

Denise Thorsen has been named one of the 20 winners of a prestigious NASA prize. Recognized for expanding access to space systems engineering, she'll receive $25,000 to boost inclusive space tech. Students from the program recently advanced in the Nanosatellite Program, showcasing their talent and dedication.

Nicole Misarti appointed director of Institute of Northern Engineering

March 01, 2024

UAF students win funds from Air Force to build a nanosatellite

February 20, 2024

Observing ice through Fresh Eyes: a winter trail visit to Shageluk

December 07, 2023

INE Director Candidate Public Forum

November 10, 2023

The public is invited to a presentation by Nicole Misarti, a final candidate for the INE director position.

May4

Apr29

Last day of instruction

April 30-May 4

Final examinations

May5

Residence halls close

Noon

May8

Deadline for faculty to post grades

Noon

See full academic calendar for more information.